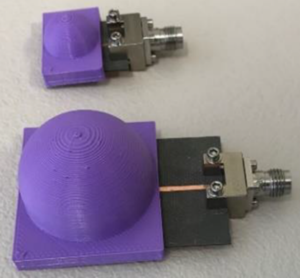

3D printing self-folding structures using Tango Plus FLX930

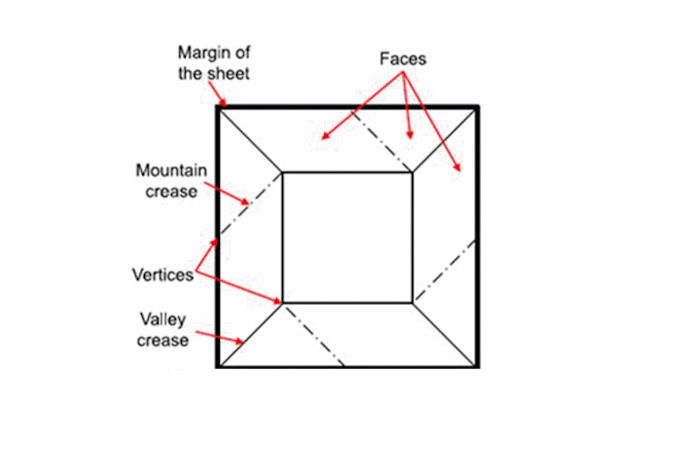

Self-folding is the ability of the structure to fold and/or unfold without human intervention or any application of external manipulation. It is known that the structure of folding object consists of two essential parts. These parts are the faces and the creases. In this paper, it is assumed that the faces could be built by using solid materials, and the crease lines can be built using soft material which provides a high bent ability. Furthermore, these two materials should be combined built without using any connections between them. Fortunately, the 3D printer provides this capability. It can print two types of different materials at the same time for the same structure. Therefore, a 3D printer is chosen to fabricate a folding structure using two types of material. These types are the Vero for solid faces and Tango plus FLX930 for the soft creases lines. The soft material at hinge part (creases lines) subjected to the load directly when the structure folds. It should have a clear view of the mechanical properties of this material. Therefore, several mechanical tests for Tango FLX930 material are operated to calculate its mechanical properties and find the force that required to fold it.

Abtan, AA, Richardson, RC and Thomas, B (2017) Analyzing the 3D Printed Material Tango Plus FLX930 for Using in Self-Folding Structure. In: International Conference for Students on Applied Engineering (ICSAE). ICSAE 2016: The International Conference for Students on Applied Engineering, 20-21 Oct 2016, Newcastle, UK. IEEE . ISBN 978-1-4673-9053-8. Read publication.