3D Printing Lightweight Antennas for Communications and Sensing

Self-Repairing Cities researchers have been working to make lightweight and unobtrusive millimetrewave antennas for communications, radar and sensing on drones and other robotic platforms. Led by Prof Ian Robertson and Dr Nutapong Somjit, the team have been pioneering a new approach to use 3D printed materials to reduce the weight of antennas without losing performance. Being able to connect drones and robots to the Cloud using the cellular network is key to realising the full potential of the Smart City. Millimetre-waves are already being used for 5G (26-28 GHz) and the next generation, 6G, is expected to make use of signals beyond 100 GHz, as recently discussed at the 6G Wireless Summit.

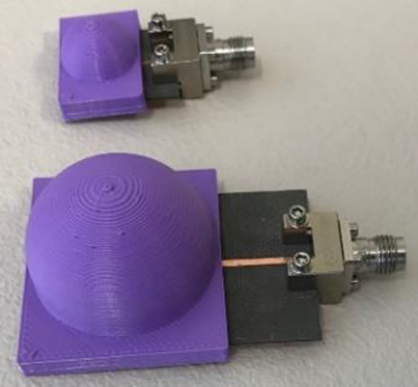

Before they could start on the design of the antennas for use above 100 GHz, the team first needed to determine which polymers were most suitable for use in electronics. Characterizing dielectric material properties of relative permittivity and loss tangent in the millimetre-wave and THz frequency bands, which are increasingly important for applications in science and engineering, requires very high precision measurement and calibration. The team addressed this by developing a novel multimodal sensor for characterizing relative permittivity of plastic polymers. The sensor offers various key advantages over any state-of-the-art material characterization techniques at millimetre-wave frequencies, including multiple characterization techniques integrated in a single device, miniaturization, much higher tolerance to changes in the measurement environment, ease of design and fabrication, and improved cost effectiveness. The team went on to characterise the dielectric properties of resin-based photocurable polymer materials for stereolithography, digital-light-processing (DLP), and polymer-jetting additive manufacturing techniques. Fourteen different materials were characterized from 0.2 to 1.4 terahertz (THz) for their comprehensive dielectric properties, e.g., refractive index, absorption coefficient, dielectric constant, and loss tangent, by using laser-based THz time-domain spectroscopy. The photocurable 3D-printing polymers were chosen owing to their suitability, in terms of printing resolution, material characteristics, and so on, for millimetre-wave (mm-wave) and THz applications. The dielectric constants of all photopolymer samples tested were found to be between 2.00 and 3.10, while the loss tangents were from 0.008 to 0.102, which are quite useful for many applications, e.g., 3D printed antennas and THz transmission lines. As well as helping chose the optimum polymers for the 3D printing of antennas, this work potentially has wider applications in Smart Cities. It may be a useful way of assisting with the recycling of plastics – a task that is beyond computer vision – either for robots out and about in the city to identify and collect plastic waste, or in main recycling centres for separating different kinds of plastic. Similarly, a nano-fluidic millimetre-wave lab-on-a-waveguide sensor for liquid-mixture characterisation was developed that could potentially be used on a robot to seek out microplastics in the environment, such as in rivers, helping to protect the natural environment in cities. Having characterised various polymers, the team turned their attention to antenna design and fabrication using 3D printing. A 220-320 GHz hemispherical lens antenna was fabricated using photopolymer-based 3D printing and directly fed by a standard WR-3 rectangular waveguide without any additional waveguide extension. The microfabrication process was based on digital light processing rapid prototyping using the Monocure 3DR3582C resin-based photocurable polymer. This gives various key advantages, including ease of antenna fabrication, manufacturing speed, and costeffectiveness due to its rapid fabrication capability. Even though the photopolymer is found to have a loss tangent of 0.034 at 320 GHz, the all-polymer lens antennas still achieve a fractional bandwidth of 37%, covering the whole 220-320-GHz WR-3 waveguide band with a measured gain of approximately 16 dBi at 0° over the whole band. A measured return loss of better than 14 dB was achieved from 220 to 320 GHz with a half-power beamwidth of approximately 12°, which is relatively constant over the whole WR-3 band.

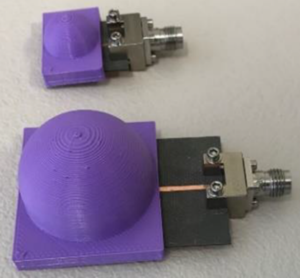

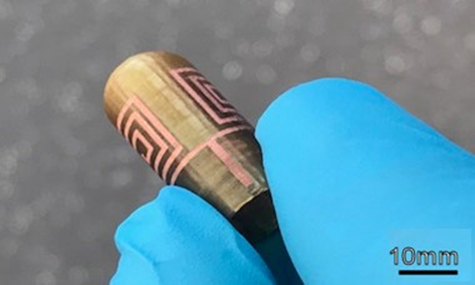

To reduce the mass of high-gain antennas, the team studied lens antennas with reduced in-fill density i.e. carefully optimised air-pocket structures. The design and three-dimensional (3D) integration of low-cost, low-loss and easy-to-fabricate 3D-printed integrated lens antennas (ILAs) for 5G broadband wireless communications in the 28 GHz frequency range was demonstrated. The ILA designs consist of an extended hemispherical lens, fed by two different types of source antennas, a substrate integrated waveguide (SIW) slot antenna array and a microstrip patch antenna (MPA) array. Results from comprehensive parametric analyses of the infill pattern and density of the 3D printed dielectric lenses were intensively investigated and characterized for their electromagnetic properties. The ILAs were fabricated using polylactic acid (PLA) as the fused deposition modelling (FDM) polymer with an optimized infill density of 50%, which speeds up prototyping time and decreases the relative permittivity, dielectric loss, manufacturing cost, and overall mass of the lens. The measurement results showed a fractional bandwidth of 10.7%, from 26.5 to 29.4 GHz, with a maximum gain of 15.6 dBi at boresight and half power beam-width of approximately 58° and 75° in the E and H planes, respectively. Through collaboration with colleagues in another EPSRC project (EP/P027687/1 A Platform for Hybrid Manufacturing Process research) the team has also successfully demonstrated the realisation of conformal antennas using an innovative hybrid additive manufacturing technique. The full details of the process have been published and the prototype is illustrated below.

Conformal antenna manufactured using an innovative hybrid additive manufacturing technique